The aluminium oxide (AL2O3) moisture sensor provides accurate determination of dew point, frost point, ppm, or relative humidity in most industrial gases.

The operating principle of the aluminum oxide sensor is that its capacitance varies with the moisture concentration. The sensor is capable of both ppm and dew point measurements in most industrial gas streams. The electronics are mounted internally and process the signal from the sensor and display the readings on the front display panel.

Aluminium Oxide Moisture Sensor Theory

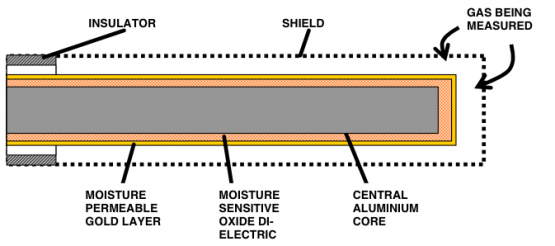

An aluminum layer on a ceramic support is anodized to form a thin porous layer of aluminum oxide. The aluminum oxide is then coated with a thin, permeable layer of gold. The gold and the aluminium layers form the sensor electrodes.

Figure 1. Cross-section of aluminium oxide sensor.

The gold layer is permeable to moisture and conductive. This forms the second electrode of a capacitor.

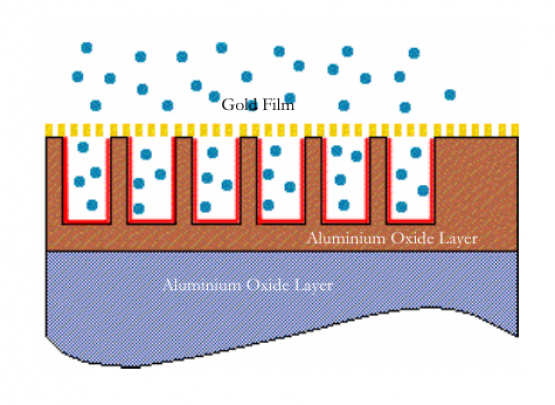

The pores in the aluminium oxide layer absorb moisture from the gas stream in amounts directly proportional to the moisture content of the gas stream.

Figure 2. Close-up view of aluminium oxide sensor.

Figure 2. Close-up view of aluminium oxide sensor.

The absorption of water molecules changes the capacitance of the sensor. The capacitance of the sensor is measured which is then converted to the moisture value.

The radius of the pores in the aluminium oxide layer make the sensor specific to water molecules.

Uses of the Aluminium Oxide Sensor

The aluminium oxide sensor is suitable for use on virtually any application where moisture measurements are required.

Industrial applications for moisture analyzers fall into two areas:

- Gas Producers: for ensuring product quality

- Gas Users: to ensure reliability of inert gas blankets.

Typical industries requiring the use of moisture measurement equipment are Semiconductor, Metal Treatment, and Plastics.