Because each oxygen analyzer measurement method has its advantages and disadvantages, it is important to choose an oxygen analyzer to suit your method application and use.

The following describes an overview of each measurement method and their advantages and disadvantages.

(1) Zirconia type measuring system:

Concentration cell system, the high conductivity temperature of solid electrolyte oxygen ions like zirconia.

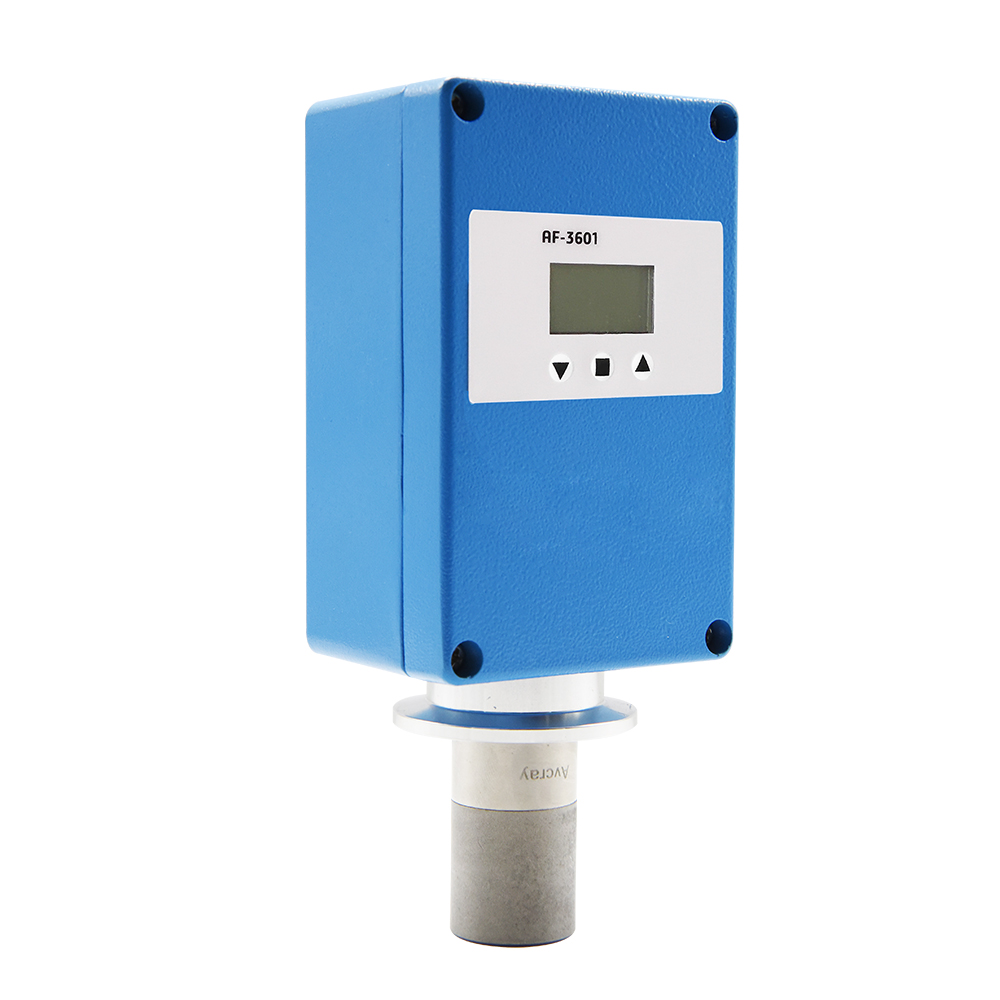

As shown in the figure, when porous platinum electrodes are attached to both, the side heating of zirconia element and the oxygen concentration of different parts of the gas are brought into contact with the corresponding surface. Zirconia is a kind of oxygen concentration pool. This phenomenon causes an electromotive force to be generated between the two electrodes. According to the Nernst equation, the proportional oxygen concentration is determined.

Advantages: It can be directly installed in the combustion process, such as boiler flue and fast loop without sampling system.

Disadvantage: If the sample gas contains combustible gas, it may completely burn the measuring cell.

(2) Zirconia type measuring system: limited current type

As shown in the figure below, if the process oxygen enters the cathode of zirconia, the elements heated to high temperature are limited, and there is a region where the current becomes uniform when the applied voltage increases. This limited current is proportional to oxygen.

Advantages: able to measure trace oxygen concentration. May require calibration in air.

Disadvantages: If the sample gas contains combustible gas, measurement errors will occur.

The presence of dust causes the gas diffusion holes on the cathode side to be blocked; the filter must be installed in the previous stage.

(3) Magnetic measuring system: paramagnetic system

This is one of the ways to utilize oxygen paramagnetism. When the sample gas contains oxygen, the oxygen is drawn into the magnetic field, thereby reducing the flow rate of the auxiliary gas in the flow B. The flow rate difference between the two streams A and B caused by the influence of the flow restriction in the stream B is proportional to the oxygen concentration of the sample gas. The flow rate is determined by the thermistor and converted into an electrical signal, and the difference is calculated as an oxygen signal.