The centrifuge oxygen content analyzer is composed of a scrubber, a dewatering filter, a fine filter (organic filter powder), a condenser, a flow meter, a gas analyzer, a complete set of sampling processing system and calibration system, and a sampling probe The unexpected part is installed inside a calibration box.

Gas analysis instrument is the core part of this system. Other parts are to ensure the long-term reliable operation of the gas analysis instrument.

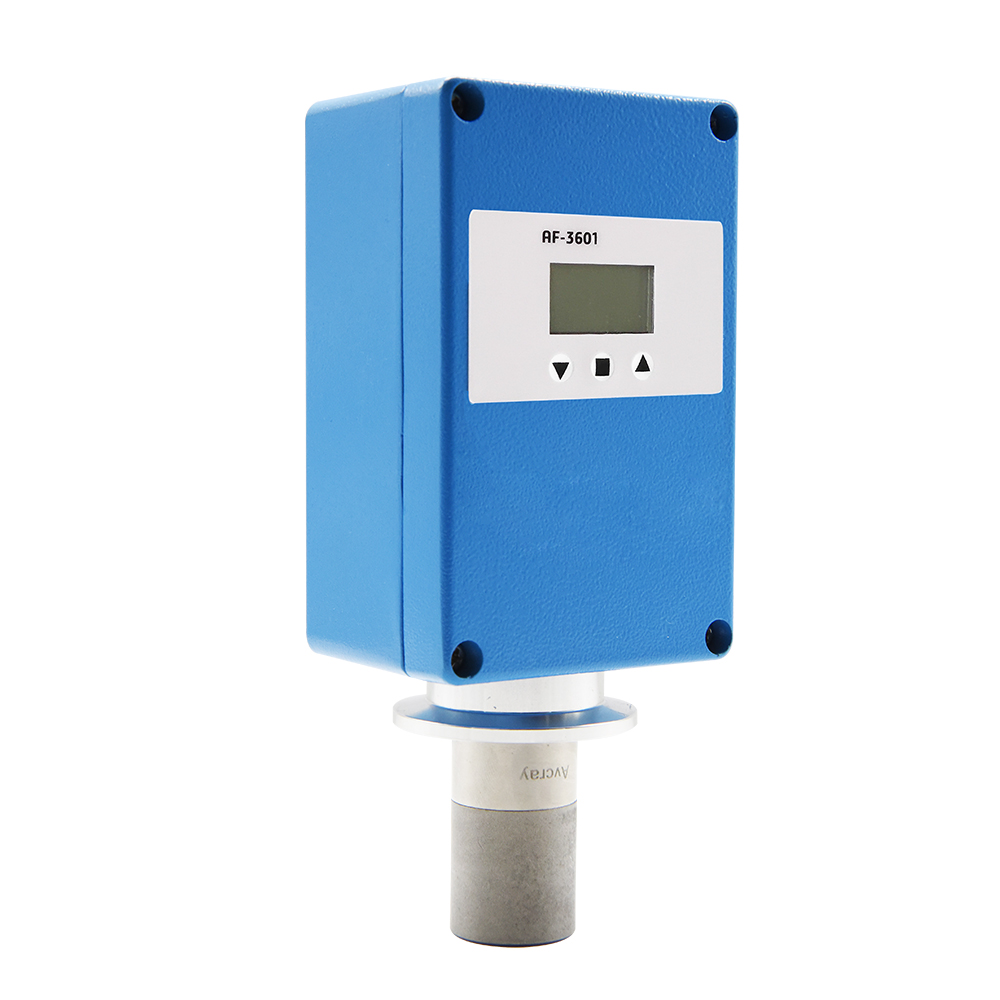

The sample gas to be tested is taken out through the sampling pipeline, and after removing water and dust through the filter, the flowmeter is sent to the analysis instrument, and the 4-200mA current signal is converted into a numerical value and displayed on the instrument.

The sampling probe should be installed in a representative process pipeline.

In the sampling state, the process sample gas enters the inside of the sampling probe. Inside the sampling probe, the dust particles in the process sample gas will be filtered in large quantities. The filtered process sample gas enters the cabinet. Rotate the manual dewatering valve, the sample gas enters the dewatering filter all the way, for the gaseous water and liquid water in the outgoing sample gas to prevent condensation in the analyzer.

After the dehumidified sample gas passes through the three-way valve, it is dried and filtered, and enters the analysis instrument through a flow meter.

System use:

1. It is used to monitor the oxygen content in the reactor of medicine and chemical industry;

2. Perform acid-base neutralization, dewatering, drying, and constant pressure on the sample gas to ensure the stable and long-term operation of the analytical instrument;

3. When the oxygen content in the reactor exceeds the preset value, the opening and closing of the nitrogen valve is automatically controlled.

Product features of centrifuge oxygen analyzer:

1. Intelligent display: self-luminous OLED display, wide observation from multiple angles;

2. Applicable explosion-proof area: Intrinsically safe flameproof composite instrument, which meets the severe use area;

3. Modular platform: freely adjust the number of preprocessing stages and functions according to actual usage, and have a wider range of adaptation;

4. Easy maintenance: one-key calibration/calibration, tool-free disassembly and maintenance, hot-swappable replacement of sensor components;

5. Customized pretreatment: backflushing the sample gas, neutralizing acid and alkali, removing organic matter, removing water, cooling, drying, stabilizing, constant current, etc.;

6. Nitrogen flow control: Equipped with a nitrogen control box, which automatically cuts off the large flow of nitrogen when the oxygen concentration is within a safe range to achieve continuous supply of small flow to meet the slight positive pressure in the centrifuge;

7. Safety: If the oxygen concentration exceeds the first-level preset alarm value, it will automatically turn on the electromagnetic regulation and nitrogen replacement until the value drops to a safe range; if the second-level preset alarm value is exceeded, the power will be automatically cut off to stop the centrifuge.