In recent years, leaks, fires, and explosions of reactors in the chemical and pharmaceutical industries have occurred frequently. Since the kettle is often filled with toxic and hazardous chemicals, the consequences of accidents are more serious than general explosion accidents. So what is the cause of the explosion? Is there any effective way to control the explosion?

Conditions required for reactor explosion

The reaction kettle must meet three conditions at the same time for combustion and explosion: combustible materials, oxygen, and ignition point. Most of the materials in the reactor are hazardous chemicals. Once leaked, they will form an explosive mixture with the air, which may cause fire and explosion if they encounter fire sources (open flames, sparks, static electricity, etc.). If the materials are toxic and hazardous substances, once they leak, they may Cause poisoning and suffocation.

Method of controlling explosion of reactor

Prevention of explosion is essentially the control of three factors. When the other two conditions cannot be avoided, controlling the oxygen concentration inside the reactor is the most important link to avoid explosion.

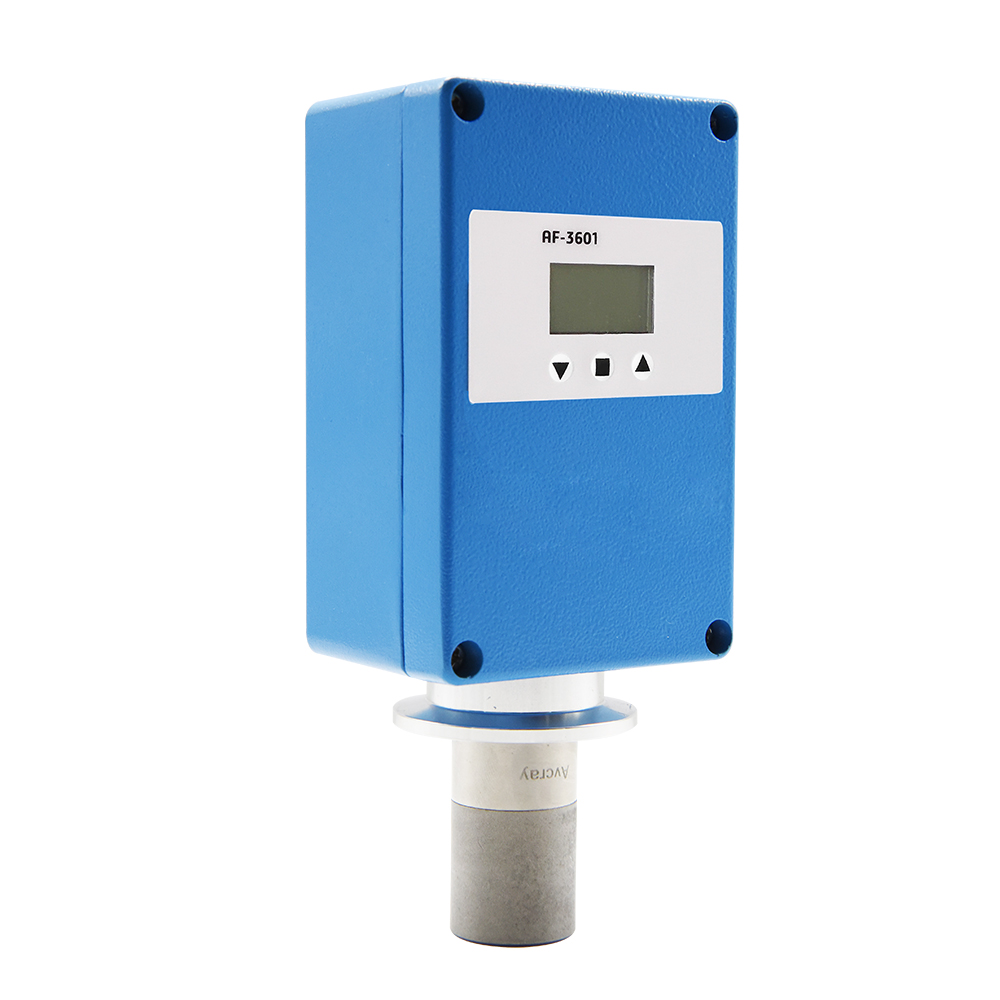

The installation of an oxygen concentration online analyzer is a more advanced method, which is to extract the sample gas in the reactor to monitor the internal oxygen concentration value in real time, and it can realize automatic interlock when the oxygen exceeds the standard.

What is the biggest problem with the reactor oxygen content analyzer at present?

The biggest problem that exists at present is due to the fact that the reactors have different materials and parameters, and the situation is complex and changeable. It is necessary to customize a special pretreatment system for different process parameters, otherwise it is difficult to achieve normal operation. Whether the reactor oxygen analyzer works and whether it can be used for a long time mainly depends on whether it can solve the following four problems:

- Whether the reactor oxygen content analyzer solves the corrosion process difficulties faced by the reactor process, the use of special pretreatment devices can effectively remove the corrosion of various acids, alkalis, and phenyl alcohol lipid organic solvents on the sensor. Compared with conventional products, The service life is extended by more than 3 times.

- Whether the reactor oxygen content analyzer has a variety of technical solutions and configurations to calmly respond to various working conditions, and can provide corresponding solutions for different feeding environments to solve corrosion problems.

- Whether the reactor oxygen content analyzer has standard output signals and multi-level switching signals, which perfectly matches the reactor control system and nitrogen filling system. According to different needs, various safety interlock functions such as sound and light alarm, nitrogen filling replacement, shutdown protection, etc. can be realized.

- Does the supplier of the reactor oxygen analyzer provide regular technical training, regular maintenance and other services?